Commercial Awareness Update – W/C 19th September 2022

September 16, 2022

Advice for New Law Students from a Recent Graduate

September 18, 2022Article by Namrata Ranpuria

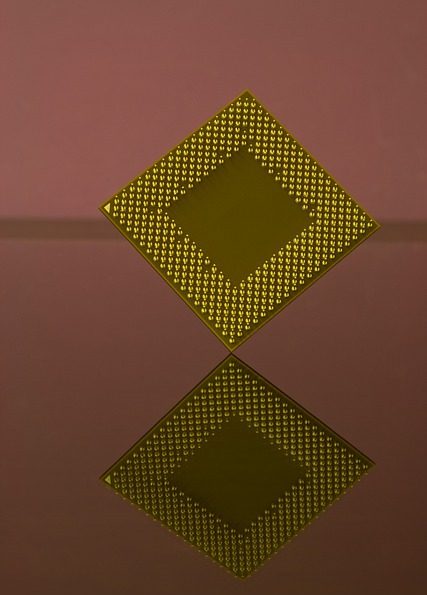

Semiconductor chips are a material that lies between conducting and insulating electricity. Therefore, they are essential to building microchips which are part of almost all electronic devices we use today. Be it phones, computers or cars. Herein lies its importance to many industries, particularly the automotive industry, as it accounts for 15% of the global semiconductor supply.

What is the impact of the shortage?

The world has seen a severe semiconductor shortage since the inception of the Covid-19 pandemic. This has resulted in severe constraints on supply chains, and hence the production of vehicles and automakers’ profits. Many automakers such as General Motors, announced in the third quarter of 2021 that their plants ran at a 60% capacity, compared to the previous year when they ran at 112%. Further, the industry in 2021 lost an estimated $210 billion in revenue. It is evident that semiconductors are essential and that their shortages have significant impacts on the turnover and profitability of automakers globally.

Why is there a shortage?

Most of the world’s semiconductors are produced in Taiwan, with 65% of the manufacturing taking place there, with a further 5% in China. Covid-19 disruptions have caused severe labour and raw material shortages, leading to significant manufacturing and shipping delays. This has been further exasperated by the China Zero-Covid policy as manufacturing and shipping have not been able to get back to normal as planned.

Another issue is the strategy of ‘Just-in-time manufacturing’, also known as lean manufacturing, which has added to this delay and shortage. Lean manufacturing is the idea that products are produced only according to the required demand, not in surplus. This means that when there is a shortage, the impact is felt suddenly and immediately, rather than a while later.

Beyond the manufacturing delays themselves, there has been a raw material shortage from the beginning of the supply chain. Neon, an important material required in the manufacturing of semiconductors is primarily supplied by two companies in Ukraine. They produce around half of the world’s neon gas. The current situation in Ukraine, namely the Russian attacks and the general political and economic unrest have halted production, hence affecting supply chains and thus the manufacturing of these essential semiconductor chips

Will the shortage abate?

While the shortage persists, for now, the question arises will this shortage ever abate?

As semiconductors are still in demand and will remain in demand for the near future, one may ask why that is the case. Relating to our daily lives, electronic devices have almost become an extension of us, they are required for us to work, live and survive. While our needs exist so will the demand for semiconductor chips. When thinking about the automotive industry this demand is likely to rise. The sole reason is the rise of electronic vehicles (EV). EVs are quite literally the future of the automotive industry, there is a strong urgency within society and businesses to become more climate-friendly and reduce their reliance on fossil fuels. The demand and the use of EVs are thus a reality that we are transitioning into. However, EVs require more semiconductor chips than a normal vehicle, and this means a clear rise in the number of semiconductors being produced.

While this exigency may be more visible in the future, it is likely to rise from now because of two key reasons. The first is the China-Taiwan tensions, as production is already slow anymore disruption will lead to further delays and an enhanced shortage. The second is the energy crisis Europe is facing at the moment, as energy (particularly gas) prices increase, there will be an increased demand for EVs and hence pressure to produce more semiconductor chips. Herein increasing the overall production needs for semiconductor chips in the automotive industry.

Taiwan and China have a strong monopoly in the production of these chips and it is necessary that tensions between the countries subside to meet this growing demand. To counteract the monopoly, the US introduced the well-awaited CHIPS and Science Act 2022 last month. This act includes semiconductor manufacturing grants, research investments and tax credit incentives for chip manufacturers. This feeds into the long-term goal of investing in and developing the domestic semiconductor manufacturing landscape in the US. Aiming to ease the pressure on highly constrained supply chains. However, it is necessary to realise that the investments and developments will take time.

Conclusion

The shortage of semiconductor chips can be seen as a prime example of how world events can affect production levels and hence an industry. Geopolitical tensions in both the east and west need to subside for operations to be smoother and abatement of semiconductor shortages. For now, however, the shortage is here to stay and the automotive industry must adapt.